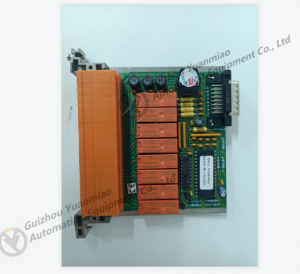

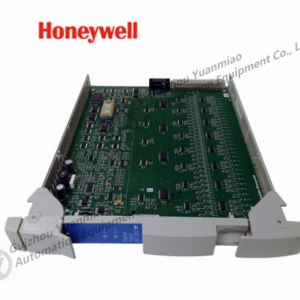

Honeywell TK-PRRR021 Analog Input Module

Honeywell TK-PRRR021 Analog Input Module Product Details:

Honeywell TK-PRR021 is an analog input module commonly used in industrial automation and control systems to receive and process analog signals for monitoring various industrial process variables. Here are some possible information about this module:

Manufacturer: Honeywell is a well-known global company in the field of industrial automation, control, and measurement technology, providing various automation and control system solutions.

Model: TK-PRR021 is the model of the analog input module used to identify a specific model of the module.

Function: The analog input module is usually used to receive analog signals, such as temperature, pressure, flow, current, or voltage, to convert these signals into digital form, so that the control system can process and analyze them. This helps to achieve monitoring and control of industrial processes.

Application areas: These types of modules are usually widely used in industrial automation systems, including various fields such as manufacturing, chemical industry, power, oil and natural gas, water treatment, etc. They are used to monitor and control various industrial process variables.

Specifications: The numerical and alphabetical sequences in the model may indicate the specifications, performance characteristics, communication interfaces, power requirements, or other specific parameters of the module. These specifications may vary by model.

Operation field: This analog input module may operate in various industrial fields, depending on customer needs and application scenarios.

Measures for anti-interference of control systems

1. Suppression of power interference. Generally, protection is achieved by setting shielded cables, PLC local shielding, and high-voltage relief components. Choosing equipment with good isolation performance, selecting excellent power, power, and signal lines should be more reasonable. For main components such as power transformers, central processing units, and programmers, conductive and magnetic materials should be used for shielding treatment to prevent the influence of external interference signals. Power adjustment and protection: Power fluctuations causing voltage distortion or burrs will have adverse effects on PLC and I/O modules. The+5V power supply required for the core components of the microprocessor is processed through multi-level filtering and adjusted using an integrated voltage regulator to adapt to the fluctuations of the AC power grid and the effects of overvoltage and undervoltage. Try to run the power lines parallel as much as possible, so that the power lines have a low impedance to ground to reduce power noise interference. The grounding method of its shielding layer is different, and the interference suppression effect is different. Generally, the secondary coil cannot be grounded. The input and output lines should use twisted pair cables and the shielding layer should be reliably grounded to suppress common touch interference. In addition, a 1:1 isolation transformer with a shielding layer can be installed to reduce interference between the equipment and ground. LC filtering circuits can also be connected in series at the power input end.

2. Anti interference measures for signal line introduction. The power line, control line, and power and I/O lines of the PLC should be wired separately, and the isolation transformer should be connected to the PLC and I/O using twisted pair cables. Separate the I/O lines and high-power lines of the PLC for wiring. If they must be in the same slot, separate and bundle the AC and DC lines. If conditions permit, it is best to separate the slots for wiring. This not only allows for maximum space distance, but also minimizes interference. In addition, using signal isolators to solve interference problems is also an ideal method. Its principle is to first modulate and transform the signal received by the PLC through semiconductor devices, then isolate and convert it through optical or magnetic sensing devices, and then demodulate and transform it back to the original signal or different signals before isolation. At the same time, isolate the power supply of the isolated signal. Ensure absolute independence between the transformed signal, power supply, and ground. As long as this isolator is added between the input and output terminals in areas with interference, the interference problem can be effectively solved.

3. Choose the correct grounding point and improve the grounding system. Good grounding is an important condition to ensure the reliable operation of PLC, which can avoid accidental voltage surge hazards. The purpose of grounding is usually twofold, one is for safety, and the other is to suppress interference. A sound grounding system is one of the important measures for PLC control systems to resist electromagnetic interference.

| HONEYWELL | J-MHM10 |

| HONEYWELL | J-MSC10 |

| HONEYWELL | TC-CCR014 |

| HONEYWELL | TC-ODK161 |

| HONEYWELL | TC-PRR021 |

| HONEYWELL | TC-PRS021 |

| HONEYWELL | TC-XXXXX1 |

| HONEYWLL | TK-PRS021 |

[Disclaimer]

Our company sells new products and discontinued products, and purchases such special products through independent channels. Guizhou Yuanmiao Automation Equipment Co., Ltd. is not an authorized distributor, distributor or representative of the featured products of this website. All product names/product images, trademarks, brands and microlabels used on this website are the property of their respective owners. Product descriptions, descriptions or sales with these name images, trademarks, brands and logos are for identification purposes only and do not represent any association or authorization with any right holders.