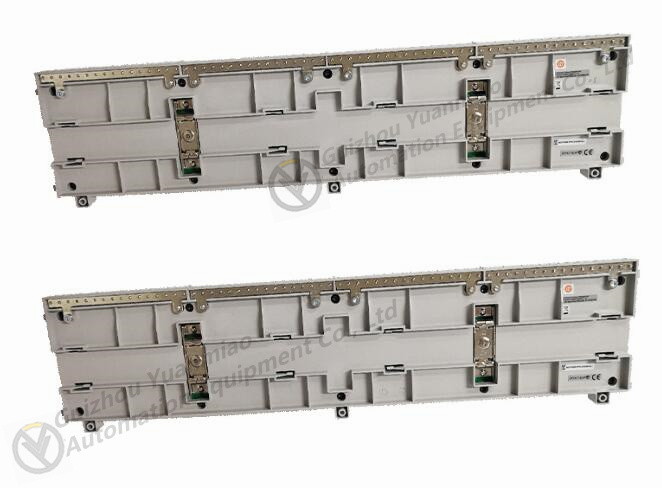

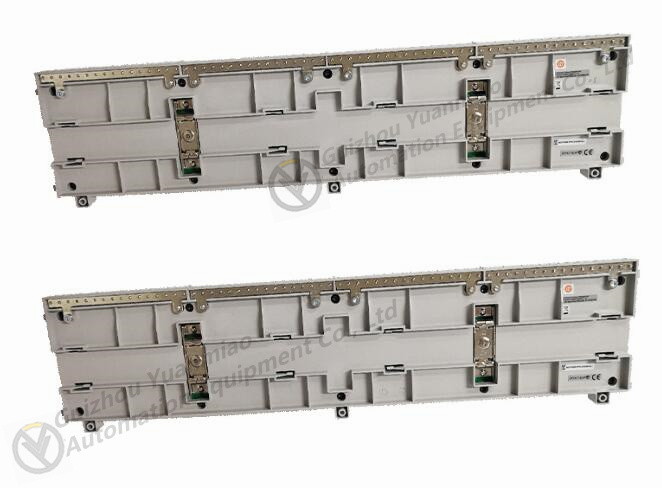

Emerson 5X00583G01 controller

HC900 DCS control system is a DCS control system developed based on loop control. The control of analog quantity is the * * * of its * * *, and the grade accuracy is 0.1. Its programming mode is not a statement or ladder diagram, but in the form of function modules. Simple function blocks only deal with a single task. Complex function blocks such as PID function blocks with input and output function blocks have all the main functions of the digital controller. The programming is relatively simple and reliable, reducing the amount of programming errors. The communication mode is Ethernet communication. During the whole equipment operation process, the monitoring program can be opened to monitor the operation status of the DCS program, and can be modified as the internal program of the lower computer DCS without interrupting the equipment process operation. The on-site installation and commissioning are very simple. The input, output and operation of all internal function blocks are analog quantities calculated by floating point. The control of temperature circuit and pressure circuit is very stable, and the processing speed of digital quantity is slower than that of PLC. The HC900 DCS control system is very suitable for the control system of industrial furnaces and kilns with temperature control as the goal and without sequential action control. The communication protocol between the HC900 DCS control system and the host computer is completely open, so it can be applied to a variety of industrial configuration software.

The grounding requirements of PLC system are relatively strict. There is an independent * * * grounding system, and other equipment related to PLC should also be reliably grounded. When multiple circuit grounding points are connected together, unexpected current will be generated, resulting in logic error or circuit damage.

The reason for different ground potential is usually that the ground point is separated too far in the physical area. When the equipment that is far away is connected by the communication cable or sensor, the current between the cable and the ground will flow through the whole circuit. Even in a short distance, the load current of large equipment can also change between it and the ground potential, Or unpredictable current can be generated directly by electromagnetic action.

It is possible to generate destructive current in the circuit between the power supply of the incorrect grounding point, so as to damage the equipment.

PLC system generally adopts one-point grounding mode. In order to improve the ability to resist common mode interference, floating ground technology can be used for analog signals, that is, the layer of signal cable is grounded at one point, the signal circuit is floating, and the insulation resistance with the ground should not be less than 50M Ω.

Remove the capacitance between wires to avoid misoperation

There is capacitance between each conductor of the cable, and the qualified cable can limit this capacitance to a certain range. Even for qualified cables, when the cable length exceeds a certain length, the capacitance between lines will also exceed the required value. When this cable is used for PLC input, the capacitance between lines may cause PLC misoperation, and many incomprehensible phenomena will occur.

These phenomena are mainly manifested as follows: the clear wiring is correct, but the PLC has no input; PLC should have some inputs but not some, that is, PLC inputs interfere with each other. To solve this problem, we should:

1. Cables twisted together with cable cores;

2. Try to shorten the length of cables used;

3. Separate cables from mutually interfering inputs;

4. Use cables.

1C31227G01 1C31203G01 1C31166G01 1X00102H01 1D54581G04

1C31169G01 1C31204G01 1C31227G02 1X00107H01 1D54582G01

1C31234G01 1C31205G01 1C31232G03 1X00126H02 1D54582G02

1C31169G02 1C31206G01 1C31233G01 1X00133H01 1D54582G03

1C31122G01 1C31107G01 1C31147G01 1X00161H01 1D54582G05

1C31125G02 1C31110G02 1C31147G02 1X00163H01 1C31192G01

1C31224G01 1C31113G01 1D42128G01 1X00163H02 1D54582G06

1C31116G04 1C31113G02 1D54416G01 1X00163H03 1C31166G02

1C31150G02 1C31113G03 1D54458G01 1X00163H04 1X00024H03

1C31132G01 1C31113G04 1D54471G02 1X00185H01 1X00093G04

1C31129G03 1C31113G05 1D54471G03 1X00377H01 1X00093G05

3A99158G01 1C31113G06 1D54540G01 1X00415H01 1X00093G06

1X00024H01 1C31116G02 1D54544G01-8 1X00416H01 1X00093G07

3A99132G02 1C31116G03 1D54557G03 1X00416H02 1X00093H08

ST24B3 1C31161G02 1D54557G07 1X00416H03 1X00093H09

5A26391H24 1C31164G02 1D54557G10 1X00416H04 1X00093G10

———————————————————-

[Disclaimer]

Our company sells new products and discontinued products, and purchases such special products through independent channels. Guizhou Yuanmiao Automation Equipment Co., Ltd. is not an authorized distributor, distributor or representative of the featured products of this website. All product names/product images, trademarks, brands and microlabels used on this website are the property of their respective owners. Product descriptions, descriptions or sales with these name images, trademarks, brands and logos are for identification purposes only and do not represent any association or authorization with any right holders.