Bently 136711-02 Proximitor Probe

Bently 136711-02 Proximitor Probe

Function: Bently Nevada mechanical condition monitoring

Detailed reference description

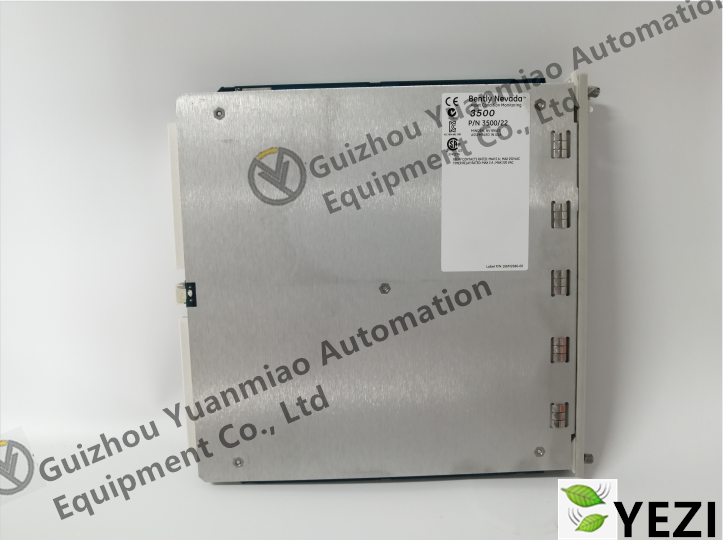

Six channel 3500/60 (without recorder) processes signals from RTD (resistance temperature detector) and TC (thermocouple).

The 3500/60 can monitor temperature or temperature differences and is typically used for radial or thrust bearing metal temperatures that comply with API670. However, it can also be used for critical process temperatures, such as compressor suction and exhaust temperatures, steam temperatures, motor stator temperatures, etc.

3500/60 adjusts the input and compares the adjusted signal with user programmable set points that can drive alarms and relay logic in the 3500 relay module. External terminal and internal barrier versions are also available.

3500/60 and 3500/61 provide the same functionality, with 3500/61 providing an additional 4-20mA recorder output for each of its six channels.

The 3500/60 and 61 modules provide six channel temperature monitoring and accept two types of resistors

Temperature detector (RTD) and thermocouple (TC) temperature inputs.

The module adjusts these inputs and compares them with user programmable alarm setpoints.

3500/60 and 3500/61 provide the same functionality except that 3500/61 is for each and 3500/60 does not.

Users program modules to perform RTD or TC temperature measurement configuration software using a 3500 rack.

Provides different I/O module RTD/TC non isolated or TC isolated versions.

Users can configure RTD/TC non isolated versions to accept any TC or a mixture of TC and RTD inputs.

The TC isolated version provides 250Vdc channel to channel isolation to prevent external interference.

For the third mock examination redundancy (TMR) configuration, temperature monitors must be installed adjacent to each other in groups of three. When used for this configuration, the system uses two types of voting to ensure accurate operation and avoid single points of failure.

System components

For these modules. The remaining 14 slots in the rack can accommodate any combination of monitors, displays, relays, displays, speakers, speakers, microphones, speakers, and/or speakers, as well as keyphasor modules and communication gateway modules.

All modules are inserted into the rack backplane, consisting of a main module and a related I/O module. For panel mounted systems, I/O modules are installed at the rear of the rack, and for partition mounted systems, they are installed above the main module.

The standard rack depth is 349mm (13.75 inches), while the partition mounting rack depth is 267mm (10.5 inches). NEMA4 and 4X weather proof housing are available when environmental protection or air purification is required.

A universal device monitor is a device used to monitor and control industrial equipment, typically used for real-time monitoring of equipment’s operational status, performance, and health status. This type of equipment is commonly used in industrial automation and equipment management systems to assist maintenance personnel and operations teams in monitoring and maintaining various types of equipment. Here are some common features and applications of this general-purpose device monitor:

Equipment monitoring and diagnosis: Universal equipment monitors are used to monitor the operational status of industrial equipment such as motors, pumps, fans, sensors, valves, etc. It can detect performance issues, anomalies, and malfunctions of devices.

Real time data collection: This type of monitor usually has a data collection function, which can collect real-time operating data of the device, such as temperature, vibration, current, pressure, etc.

Performance analysis: Universal device monitors typically have data analysis capabilities that can analyze collected data to identify potential issues, trends, and anomalies.

Alarm and notification: When there is a problem or abnormality with the equipment, the monitor can trigger alarms and notifications to enable operation and maintenance personnel to take necessary measures.

Remote monitoring: Some monitors have remote monitoring capabilities, allowing operation and maintenance personnel to remotely access the status and data of devices through the network.

Visualization interface: The monitor usually has a user-friendly visualization interface, allowing users to easily view the status and data of the device.

Equipment maintenance: This type of equipment helps predict equipment maintenance needs, enabling the operations team to carry out planned maintenance, reducing downtime and repair costs.

Industrial automation: General equipment monitors are widely used in industrial automation and equipment management systems, helping to improve equipment reliability and efficiency.

Product recommendation:

Bently vibration probe 330106-05-30-10-02-00

Bently vibration probe 330500-00-00

Bently vibration probe 330905-00-12-10-10-CN

Bently vibration probe 330907-05-30-10-02-00

Bently vibration probe 330910-00-03-50-02-00

Bently vibration probe secondary instrument 105M6193-01

Bently axis displacement transmitter 991-25-50-01-00

Bently axis displacement probe 330104-00-12-10-02-CN

Bently shaft vibration probe 330104-00-06-10-02-00

Bently speed probe 70085-1010-330 \ AI-TEK

Bently 3300XL Extension Cable 330130-045-00-00

Bently sensor 330101-00-24-10-02-CN

Bently sensor 330101-00-36-10-02-CN

Bently sensor 330101-00-48-50-02-CN

Bently sensor 330130-045-03-05

Bently sensor 330130-045-03-CN

Bently sensor 9200-01-01-10-00

Bently cable 16710-20

Bently cable 330130-040-02-CN

Bently cable 330130-040-02-05

Bently eddy current sensor probe 330103-00-05-10-02-00

Bently module 3500/05-02-04-00-00

Bently module 3500/42-04-CN

Bently module 3500/22-01-02-CN

Bently Proximitor 330180-12-CN

Bently Proximitor 330180-90-CN

Bently Proximitor 330180-51-CN

Bently Proximitor 330180-51-05

Bently Proximitor 330180-X1-CNMOD.: 143416-99

Bently Proximitor 330730-080-01-00

Bently Proximitor 330780-50-00

Bently Proximitor 330780-51-00

Bently Proximitor 330850-51-CN

Bently Proximitor 330850-51-05

[Disclaimer]

Our company sells new products and discontinued products, and purchases such special products through independent channels. Guizhou Yuanmiao Automation Equipment Co., Ltd. is not an authorized distributor, distributor or representative of the featured products of this website. All product names/product images, trademarks, brands and microlabels used on this website are the property of their respective owners. Product descriptions, descriptions or sales with these name images, trademarks, brands and logos are for identification purposes only and do not represent any association or authorization with any right holders.

Reviews

There are no reviews yet.