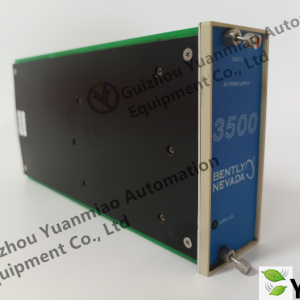

3500/22M Transient Data Interface Module

3500/22M is a transient data interface module developed by Bently Nevada. It serves as an interface for software compatible with the 3500 monitoring system (System 1 status monitoring and diagnostic software and 3500 system configuration software). TDI combines the 3500/20 rack interface module (RIM function) with communication processors (such as TDXnet) to collect data.

3500/22M features

In the 3500 rack, TDI is located in the slot next to the power supply. In order to continuously collect steady-state and transient dynamic (waveform) data and transmit this data to the host software through an Ethernet link, it interacts with M-series monitors (3500/40M, 3500/42M, etc.).

TDI has traditional static data collection capabilities. However, TDI can also use optional channels to enable disk recording of dynamic, high-resolution transient data.

Function Description

The 3500 rack contains communication processing functions for TDI. Although TDI performs some tasks shared by the entire rack, it is not a critical component of the monitoring system and is not related to the effectiveness of autonomous mechanical protection in monitoring the entire system.

Each 3500 rack requires one TDI or RIM, which always occupies slot 1. (Next to the power supply).

The link between the 3500 monitoring system and compatible software is called the 3500/22M Transient Data Interface (TDI) (System 1 status monitoring and diagnostic software and 3500 system configuration software). TDI combines the 3500/20 Rack Interface Module (RIMfunctionality) with a communication processor (such as TDXnet) to collect data.

place

In the 3500 rack, TDI is located in the slot next to the power supply. In order to continuously collect steady-state and transient dynamic (waveform) data and transmit this data to the host software through an Ethernet link, it interacts with M-series monitors (3500/40M, 3500/42M, etc.). TDI has traditional static data collection capabilities. However, TDI can also use optional channels to enable disk recording of dynamic, high-resolution transient data.

The 3500 rack contains communication processing functions for TDI. Although TDI performs some tasks shared by the entire rack, it is not a critical component of the monitoring system and is not related to the effectiveness of autonomous mechanical protection in monitoring the entire system.

Each 3500 rack requires one TDI or RIM, which always occupies slot 1. (Next to the power supply).

Configure key lock

It is used to switch the 3500 rack between “RUN” and “GRAM” modes. RUN mode can prevent configuration modifications while allowing the rack to operate normally. The rack can be configured locally or remotely, while still operating normally in Program mode. The switch can be kept in the running or programming position by removing the key from any position on the rack. You can prevent unnecessary rack reconfiguration by locking the switch in the running position. Whenever remote reconfiguration of the rack is required, the switch can be locked in the Program position.

I/O module signal common terminal

Both versions of TDI I/O modules now have a 2-pin connector used to connect the signal common terminal to the single point instrument ground of the rack. After performing this operation, to isolate the signal common terminal from the chassis (safety) ground, slide the selector switch on the power input module (PIM) side in the direction of the “HP” arrow.

data acquisition

Keyphasor input

Supports four Keyphasor signals for the 3500 system.

The number of dynamic channels in the activity determines the speed range support.

Supports multiple speed inputs per revolution, up to a maximum of 20 kHz.

Start/slide data

Collect data at a predetermined speed and time interval; The increase and decrease speed intervals of individual programming.

After detecting the machine speed within one of the two programmable windows, temporary data collection begins.

The memory capacity of a module is the only limit on the number of instantaneous events that can be collected.

Collect data at a predetermined speed and time interval; The increase and decrease speed intervals of individual programming.

After detecting the machine speed within one of the two programmable windows, temporary data collection begins.

The memory capacity of a module is the only limit on the number of instantaneous events that can be collected.

Alarm data collection

Collect 2.5 minutes of waveform data every 10 seconds before the alarm, and 1 minute of waveform data every 10 seconds after the alarm.

Data before and after the alarm.

Static values collected at one second intervals within 10 minutes before and 1 minute after the event.

Collect static values at 100 millisecond intervals 20 seconds before and 10 seconds after the event.

Attention: Due to the large number of products from our company, the pictures cannot match each other. Please contact me to confirm the actual product!

Related product videos:

.Our company is committed to through the installation of control systems for spare parts service for you and drive to provide spare parts support, we have a lot of internal inventory, including (DCS, PLC, CNC), the panel controller and HMI, industrial PC, drive, power supply and production control system and servo motor parts, reduce the maintenance cost of spare parts of you, We’ve also released a lot of new hardware to help support your existing installation or take advantage of the latest technology.

Related products:

| BENTLY | 3500/15 |

| BENTLY | 3500/20 |

| BENTLY | 125840-02 |

| BENTLY | 3500/53 |

| BENTLY | 1X35668 |

| BENTLY | 3500/22M |

| BENTLY | 3500/22M |

| BENTLY | 3500/25 |

| BENTLY | 3500/42M |

[Disclaimer]:

Our company sells new products and discontinued products, and purchases such special products through independent channels. Guizhou Yuanmiao Automation Equipment Co., Ltd. is not an authorized distributor, distributor or representative of the featured products of this website. All product names/product images, trademarks, brands and microlabels used on this website are the property of their respective owners. Product descriptions, descriptions or sales with these name images, trademarks, brands and logos are for identification purposes only and do not represent any association or authorization with any right holders.

Related products: https://www.2mwww.com/product-category/bently/