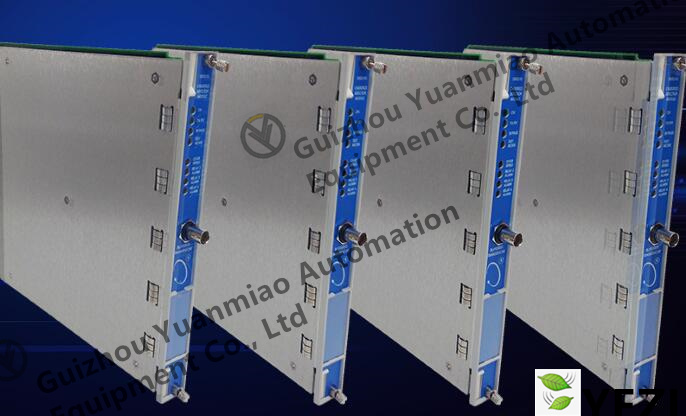

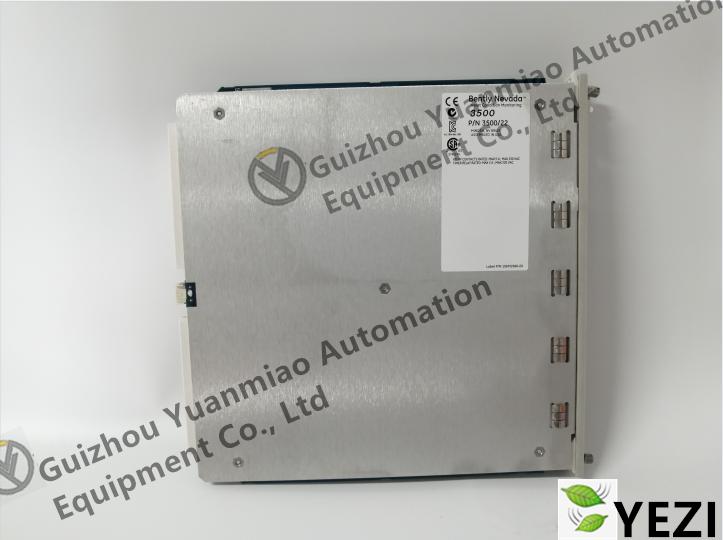

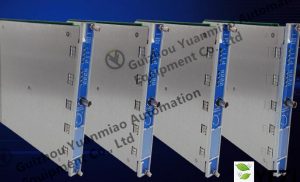

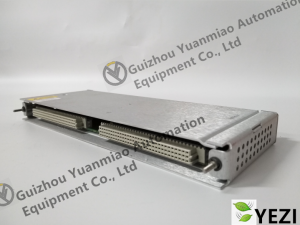

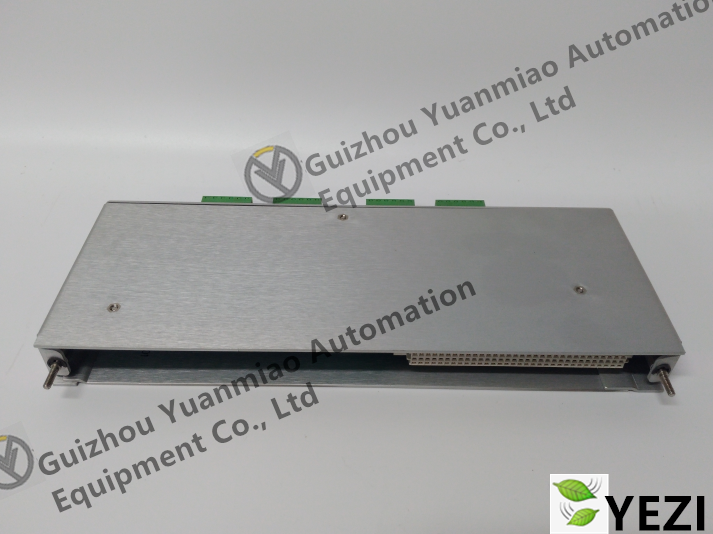

133450-01/Bently Nevada Bentley Monitoring System Spare Parts

133450-01/Bently Nevada Bentley Monitoring System Spare Parts

The displacement detection module is usually applied in industrial vibration monitoring, mechanical equipment health monitoring, and other aspects. This type of displacement detection module is usually used to measure the displacement, vibration, deformation and other parameters of objects or mechanical systems, in order to evaluate the working status and performance of the equipment.

Here are some possible application areas:

Industrial production equipment monitoring: The displacement detection module can be used to monitor the vibration and displacement of industrial equipment such as generators, turbines, compressors, etc., in order to determine their operating status, health status, and possible faults.

Conveyor belt and mechanical system monitoring: In the manufacturing and logistics fields, displacement detection modules can be used to monitor the operation of conveyor belts, production lines, and other mechanical systems, helping to predict maintenance needs and avoid sudden failures.

Building structure monitoring: The displacement detection module can be used to monitor the deformation and vibration of buildings, bridges, and other infrastructure to ensure their safety and stability.

Wind turbine monitoring: In the field of renewable energy, displacement detection modules can be used to monitor the vibration and displacement of wind turbines, helping to optimize power generation efficiency and extend equipment life.

Aerospace field: In aerospace engineering, displacement detection modules can be used to monitor the vibration and structural changes of aircraft, rockets, and other vehicles to ensure their flight safety and performance.

Usually used for vibration monitoring of industrial equipment and mechanical health monitoring. A vibration monitor is a critical device used to monitor the vibration level of equipment, in order to evaluate its working status, performance, and potential faults.

The main functions and uses of vibration monitors may include:

Vibration detection: The vibration monitor can detect the vibration situation of the equipment in real time, including the frequency, amplitude, phase, etc. of the vibration.

Abnormal alarm: When the vibration of the equipment exceeds the preset threshold, the vibration monitor can trigger an alarm to notify the operator that there may be a problem with the equipment.

Mechanical health monitoring: By analyzing vibration data, vibration monitors can help evaluate the mechanical health status of equipment, detect early mechanical problems, and achieve preventive maintenance.

Fault diagnosis: Vibration monitors can help identify possible types of faults, such as imbalance, bearing damage, mechanical looseness, etc., by analyzing vibration patterns and characteristics.

Data recording and analysis: Some vibration monitors have data recording and analysis functions, which can collect and store vibration data for subsequent analysis and trend monitoring.

BENTLY 128229-01 vibration monitor may be suitable for the following application areas:

Power plant: used to monitor the vibration of equipment such as generator sets, turbines, transformers, etc.

Industrial production: used to monitor the vibration of mechanical equipment on production lines, such as pumps, fans, compressors, etc.

Manufacturing industry: used for vibration monitoring of mechanical processing equipment to ensure production quality and equipment stability.

In the field of oil and natural gas, it is used to monitor the vibration of equipment such as drilling rigs, centrifuges, and compressors.

Product recommendation:

Bently vibration probe 330106-05-30-10-02-00

Bently vibration probe 330500-00-00

Bently vibration probe 330905-00-12-10-10-CN

Bently vibration probe 330907-05-30-10-02-00

Bently vibration probe 330910-00-03-50-02-00

Bently vibration probe secondary instrument 105M6193-01

Bently axis displacement transmitter 991-25-50-01-00

Bently axis displacement probe 330104-00-12-10-02-CN

Bently shaft vibration probe 330104-00-06-10-02-00

Bently speed probe 70085-1010-330 \ AI-TEK

Bently 3300XL Extension Cable 330130-045-00-00

Bently sensor 330101-00-24-10-02-CN

Bently sensor 330101-00-36-10-02-CN

Bently sensor 330101-00-48-50-02-CN

Bently sensor 330130-045-03-05

Bently sensor 330130-045-03-CN

Bently sensor 9200-01-01-10-00

Bently cable 16710-20

Bently cable 330130-040-02-CN

Bently cable 330130-040-02-05

Bently eddy current sensor probe 330103-00-05-10-02-00

Bently module 3500/05-02-04-00-00

Bently module 3500/42-04-CN

Bently module 3500/22-01-02-CN

Bently Proximitor 330180-12-CN

Bently Proximitor 330180-90-CN

Bently Proximitor 330180-51-CN

Bently Proximitor 330180-51-05

Bently Proximitor 330180-X1-CNMOD.: 143416-99

Bently Proximitor 330730-080-01-00

Bently Proximitor 330780-50-00

Bently Proximitor 330780-51-00

Bently Proximitor 330850-51-CN

Bently Proximitor 330850-51-05

[Disclaimer]

Our company sells new products and discontinued products, and purchases such special products through independent channels. Guizhou Yuanmiao Automation Equipment Co., Ltd. is not an authorized distributor, distributor or representative of the featured products of this website. All product names/product images, trademarks, brands and microlabels used on this website are the property of their respective owners. Product descriptions, descriptions or sales with these name images, trademarks, brands and logos are for identification purposes only and do not represent any association or authorization with any right holders.