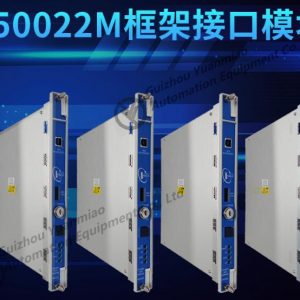

BENTLY 3500/46M Gas Turbine Card Hydraulic Monitor to Drive Power LED

The 3500/46MHydro Monitor is a four channel instrument that can accept inputs from proximity sensors, seismic sensors, dynamic pressure sensors, and air gap sensors. The monitor adjusts the signal to provide vibration, position, and static and dynamic pressure measurements. Then it compares the adjusted signal with a user programmable alarm. The Hydro Radial Vibration channel combines shaft clearance motion with NX amplitude to provide measurement values for alerting in the event of safety pin failure

BENTLY3500/46M Hydraulic Monitor to Drive Power LED

3500/46M is a serial communication protocol discovered by Modicon in 1979, used to transmit data between industrial electronic devices through serial lines. RS-485 Modbus Usage RS-485 is used for transmission lines. It should be noted that Modbus is a software protocol and not a hardware protocol. It is divided into two parts: Modbus master and Modbus slave. In an RS-485 Modbus network, there is one host and 127 slaves, each with a unique address from 1 to 127. In this MAX485 Arduino project, we will use Arduino Uno as the slave for serial communication.

A universal device monitor is a device used to monitor and control industrial equipment, typically used for real-time monitoring of equipment’s operational status, performance, and health status. This type of equipment is commonly used in industrial automation and equipment management systems to assist maintenance personnel and operations teams in monitoring and maintaining various types of equipment. Here are some common features and applications of this general device monitor:

Equipment monitoring and diagnosis: Universal equipment monitors are used to monitor the operational status of industrial equipment such as motors, pumps, fans, sensors, valves, etc. It can detect performance issues, anomalies, and malfunctions of devices.

Real time data collection: This type of monitor usually has a data collection function, which can collect real-time operating data of devices, such as temperature, vibration, current, pressure, etc.

Performance analysis: Universal device monitors typically have data analysis capabilities that can analyze collected data to identify potential issues, trends, and anomalies.

Alarm and notification: When there is a problem or abnormality with the equipment, the monitor can trigger alarms and notifications, so that operation and maintenance personnel can take necessary measures.

Remote monitoring: Some monitors have remote monitoring capabilities, allowing operation and maintenance personnel to remotely access the status and data of devices through the network.

Visualization interface: The monitor usually has a user-friendly visualization interface, allowing users to easily view the status and data of the device.

Equipment maintenance: This type of equipment helps predict equipment maintenance needs, enabling the operation and maintenance team to carry out planned maintenance, reducing downtime and repair costs.

Industrial automation: General equipment monitors are widely used in industrial automation and equipment management systems, helping to improve equipment reliability and efficiency.

Product recommendation:

Bently vibration probe 330106-05-30-10-02-00

Bently vibration probe 330500-00-00

Bently vibration probe 330905-00-12-10-10-CN

Bently vibration probe 330907-05-30-10-02-00

Bently vibration probe 330910-00-03-50-02-00

Bently vibration probe secondary instrument 105M6193-01

Bently axis displacement transmitter 991-25-50-01-00

Bently axis displacement probe 330104-00-12-10-02-CN

Bently shaft vibration probe 330104-00-06-10-02-00

Bently speed probe 70085-1010-330 \ AI-TEK

Bently 3300XL Extension Cable 330130-045-00-00

Bently sensor 330101-00-24-10-02-CN

Bently sensor 330101-00-36-10-02-CN

Bently sensor 330101-00-48-50-02-CN

Bently sensor 330130-045-03-05

Bently sensor 330130-045-03-CN

Bently sensor 9200-01-01-10-00

Bently cable 16710-20

Bently cable 330130-040-02-CN

Bently cable 330130-040-02-05

Bently eddy current sensor probe 330103-00-05-10-02-00

Bently module 3500/05-02-04-00-00

Bently module 3500/42-04-CN

Bently module 3500/22-01-02-CN

Bently Proximitor 330180-12-CN

Bently Proximitor 330180-90-CN

Bently Proximitor 330180-51-CN

Bently Proximitor 330180-51-05

Bently Proximitor 330180-X1-CNMOD.: 143416-99

Bently Proximitor 330730-080-01-00

Bently Proximitor 330780-50-00

Bently Proximitor 330780-51-00

Bently Proximitor 330850-51-CN

Bently Proximitor 330850-51-05

[Disclaimer]

Our company sells new products and discontinued products, and purchases such special products through independent channels. Guizhou Yuanmiao Automation Equipment Co., Ltd. is not an authorized distributor, distributor or representative of the featured products of this website. All product names/product images, trademarks, brands and microlabels used on this website are the property of their respective owners. Product descriptions, descriptions or sales with these name images, trademarks, brands and logos are for identification purposes only and do not represent any association or authorization with any right holders.