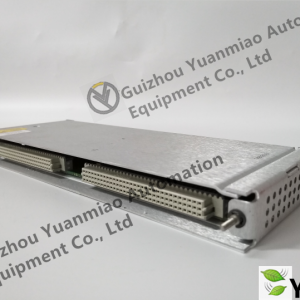

Bently 125840-01 Input card

BENTLY 135137-01 feeder management relay is a microprocessor based protection and control relay designed for distribution systems. It provides advanced protection, control, monitoring, and communication functions to improve the reliability and efficiency of the power system.

BENTLY 135137-01 relay can be used to protect feeders in various applications, including distribution systems, industrial power systems, and renewable energy systems. Capable of detecting various fault types such as overcurrent, undercurrent, overvoltage, undervoltage, grounding, etc., providing fast and accurate protection.

This relay has multiple communication options, including Ethernet, Modbus, and IEC 61850 protocols, allowing it to connect to other devices in the power system. It also has advanced monitoring and control functions, such as load shedding, fault isolation, and automatic reclosing, which help to minimize downtime and improve the reliability of the power system.

The BENTLY 135137-01 relay has a user-friendly interface with a large graphical display screen and easy-to-use menu navigation, making it easy to set up and configure. It is also designed to operate reliably under harsh environmental conditions, with features such as sturdy design, conformal coating, and advanced diagnostic capabilities.

Overall, the BENTLY 135137-01 feeder management relay is a multifunctional and reliable device that provides advanced protection and control for power distribution systems.

Bentley 135137-01 Tachometer I/O Module is an input/output module used in tachometer systems. Its main function is to receive and send signals related to the tachometer, achieving data acquisition and control functions.

Specifically, the functions of the tachometer I/O module may include the following aspects:

Input signal reception: This module typically has the ability to receive signals from tachometer sensors or other related sensors. These sensors can be devices used to measure the rotational speed of rotating objects, such as magnetic sensors, Hall effect sensors, or photoelectric sensors. The module receives the output signals of these sensors and converts them into digital signals for processing.

Data processing and storage: The module may contain processors and memory for processing and storing input signals. It can perform digital signal processing algorithms such as filtering, amplification, calibration, etc. to extract useful information. In addition, the module can also store the processed data in memory for future use or transmission to other systems.

Output signal generation: In addition to receiving input signals, the module can also generate output signals for control and indication. For example, it can generate pulse signals, voltage signals, or digital signals according to the requirements of the tachometer system to drive other devices or systems to perform corresponding operations.

Communication interface: The tachometer I/O module usually has the ability to communicate with other systems or devices. It can provide standard digital interfaces, such as serial communication interfaces (such as RS-232, RS-485) or Ethernet interfaces, for data exchange, transmission, or remote monitoring with other devices.

The additional software of 125680-01 intelligent function kit for processing or separating liquids saves users more time. As part of the pre installed software package, the wizard will visually guide users through the debugging process. The system is parameterized and the axis is automatically referenced. Sequencing is carried out on an intuitive basis, with the help of ready-made functional modules, which can be completed in a few minutes. Due to the flexible combination of hardware platforms and innovative software, even complex line movements of 125680-01 can be reproduced through simple graphic programming. With the help of appropriate functional modules, production line integration can also be easily achieved.

135137-01 is a position/O module with internal terminals, used for proximitors, RPTs, or DC LVDTs. It was designed and developed by Bentley Nevada. It is part of the 3500/45 monitoring system. The position monitor is a 4-channel device that can receive inputs from rotary potentiometers, proximity sensors, DC linear variable differential transformers, AC linear variable differential transformers, and rotary position sensors (RPTs).

The main function of the position monitor is to provide the following functions:

● By continuously comparing monitoring parameters and predefined alarm settings, alarms are triggered to protect the machine.

● Important machine knowledge for operation and maintenance personnel

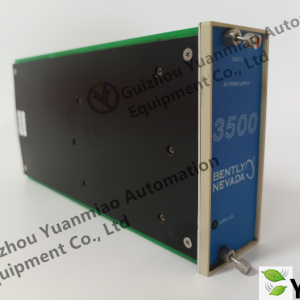

The 3500/15 AC and DC power supplies accept a wide range of input voltages and convert them into voltages acceptable to other 3500 modules. The following power supplies are available for the 3500 series machine protection system: – General AC

Power supply – High voltage DC power supply – Low voltage DC power supply

| BENTLY | 167699-02 |

| BENTLY | 3300/16-14-01-03-00-00-01 |

| BENTLY | 3500/15 |

| BENTLY | 3500/20 |

| BENTLY NEVADA | 125760-01 |

| BENTLY NEVADA | 125768-01 |

| BENTLY NEVADA | 129478-01 |

| BENTLY NEVADA | 3500 |

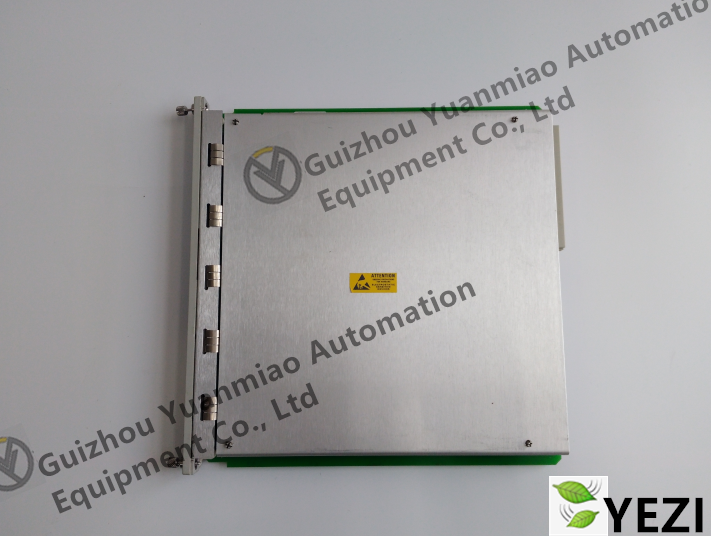

[Disclaimer]

Our company sells new products and discontinued products, and purchases such special products through independent channels. Guizhou Yuanmiao Automation Equipment Co., Ltd. is not an authorized distributor, distributor or representative of the featured products of this website. All product names/product images, trademarks, brands and microlabels used on this website are the property of their respective owners. Product descriptions, descriptions or sales with these name images, trademarks, brands and logos are for identification purposes only and do not represent any association or authorization with any right holders.