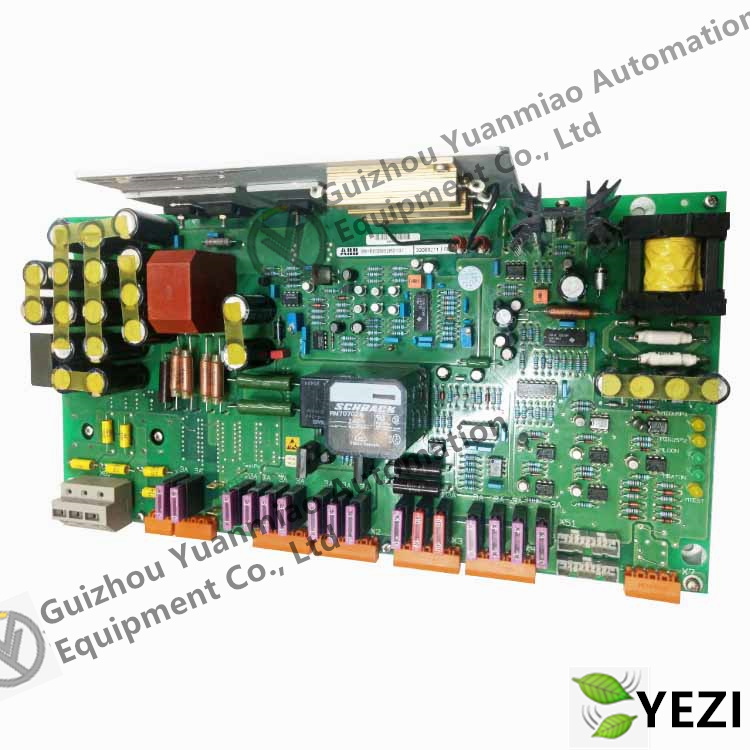

ABB KUC720AE01 3BHB003431R0001 controller

DCS is the abbreviation of distributed control system, which is applied in thermal power, large-scale petrochemical, steel and other industries, and is initially skilled in analog calculation and control of thermal power and other places where multiple controllers coordinate control; PLC is the abbreviation of logic controller, which is widely used and is initially skilled in logic control and sequential control places such as the automotive industry. At this stage of development, there is no obvious boundary between DCS and (PLC+SCADA) systems, and their system structures and functions are basically the same in general industries. Application Scope PLC is mainly used in the field of process control in aerospace, power generation, petrochemical, steel, tobacco, pharmaceuticals, food, petrochemical, metallurgy, mining, water treatment, transportation, and other fields. Power plants are used in auxiliary workshops of large thermal power plants, water and electricity master control, and so on. DCS is mainly used in process control, mainly in automation fields such as power generation, petrochemical, steel, tobacco, pharmaceuticals, food, petrochemical, metallurgy, mining, etc. Among them, the main control units of aerospace, thermal power, nuclear power, large-scale petrochemical, and steel must currently use DCS for control. The application of DCS and PLC in process control is mutually penetrating. In general, DCS can be used in all fields where PLC can be used functionally; PLC+SCADA has all the functions of DCS except for direct-fired engines, large-scale thermal power master control, nuclear power master control, steel plant master control, and large-scale petrochemical master control. Comparing the hardware components of PLC and DCS, the architecture of PLC+SCADA is basically the same as that of DCS, or the architecture of PLC is more flexible. The subtle difference is that the hardware hot standby redundancy mode of PLC is dual rack, dual power supply, dual processor, and dual network card redundancy mode. In the early days, DCS used dual power supply and dual DPUs (distributed processing units) to form a redundant architecture on the same rack, while now DCS uses two integrated DPUs to form a hot standby redundancy architecture. The advantages and disadvantages of the two methods are not compared here. In terms of hardware, PLC is unfavorable, and integrated CPU (DPU/CPU refers to the same processor) is more conducive to reduction. The redundancy architecture of PLC has not changed due to the early design architecture, and now some domestic PLCs and DCS redundancy architectures are the same. There is a difference between PLC and DCS in hardware. PLC does not have a redundant IO switching module, which may be due to the lack of demand for this module in the current PLC application field. In recent years, there has been a development in the design architecture of PLC. Between the CPU and non local rack IO modules and intelligent devices, * * * mainly promotes the bus communication mode, but instead uses industrial Ethernet. The bus is only used between local communication modules and devices, even Ethernet 1-station infrastructure. DTM functions can directly configure devices with standard TCP protocols, making communication more convenient than DCS.

KUC720AE01 3BHB003431R0001

ABB robots provide rich I/O communication interfaces, which can easily communicate with peripheral devices.

Description of ABB robot I/O communication interface

1. Common signal processing provided by ABB standard I/O includes digital input di, digital output do, analog input ai and analog output AO. And conveyor chain tracking.

2. ABB robots can be equipped with standard ABB PLC. It saves the trouble of communication with external PLC, and can realize PLC related operations on the robot’s teaching pendant.

KUC720AE01 3BHB003431R0001

| ABB | 3BHB003154R0101 |

| ABB | 3BHB003688R0001 |

| ABB | 3BHB003688R0101 |

| ABB | 3BHB003689 |

| ABB | 3BHB004027R0101 |

| ABB | 3BHB005171R0101 |

| ABB | 3BHB005243R0105 |

| ABB | 3BHE009681R0101 |

| ABB | 3BHE021951R0124 |

| ABB | 3BHE024747R0101 |

| ABB | 3BHE027632R0101 |

| ABB | 3BHE039203R0101 |

[Disclaimer]

Our company sells new products and discontinued products, and purchases such special products through independent channels. Guizhou Yuanmiao Automation Equipment Co., Ltd. is not an authorized distributor, distributor or representative of the featured products of this website. All product names/product images, trademarks, brands and microlabels used on this website are the property of their respective owners. Product descriptions, descriptions or sales with these name images, trademarks, brands and logos are for identification purposes only and do not represent any association or authorization with any right holders.