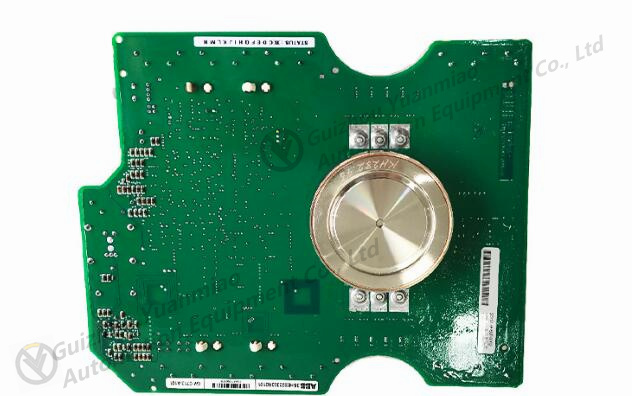

ABB 5SHX0660F0002 main board

5SHX0660F0002 3BHE022333R0101/GVC713 industrial control card DCS system automation equipment

Click the Channel tab. Select the appropriate gain for each channel. If you want to configure all channels at the same time, select the channel drop-down list, scroll to the bottom, and then select all channels. For a detailed description of each setting, see the SCXI-1102/B/C Software Configurable Settings section. Click Apply. 4. Click Attachment. Select the attachment to connect to the module. When the configuration is complete, click OK. The traditional NI-DAQ (traditional) chassis and SCXI-1102/B/C should now be configured correctly. If you need to change the module configuration, right-click the module and repeat steps 1 to 4. Test the system according to the steps in the “Self test verification troubleshooting” section of “About SCXI-1102/B/C” in chapter * * *.

·ABB has provided ABB UniGear ZS1 digital medium-voltage switchgear, ABB AbilityTM MyRemoteCare equipment health management and ABB ZEE600 intelligent power distribution management solutions for Qilu Petrochemical Liuteng substation, further improving the power reliability and operation and maintenance efficiency of the enterprise site.

·Relying on hundreds of years of industry experience and * * * electrical technology, ABB provides full-life cycle solutions for the distribution system in the petrochemical industry, helping the petrochemical industry to realize the * * * operation of reducing costs and increasing efficiency.

On the 73rd anniversary of the founding of the People’s Republic of China, under the superimposed situation of energy conservation, emission reduction and intelligent manufacturing, ABB takes low-carbon intelligence as the starting point of practicing social responsibility, and uses the means of digitalization and electrification to accelerate the establishment of an efficient and clean comprehensive energy management system in the petrochemical industry, contributing to China’s green ecological construction and industrial sustainable development.

For petrochemical enterprises, the characteristics of complex production process, large-scale production equipment, and strong continuity of production process are the true reflection of the “double carbon” goal. Enterprises urgently need to find a digital carbon reduction path suitable for their own transformation and upgrading, tap the potential of cost reduction and efficiency increase from equipment maintenance, energy efficiency management, intelligent operation and maintenance, and achieve win-win economic and environmental benefits on the premise of * * * stable production.

Affiliated to Sinopec Group, Qilu Petrochemical has always earnestly implemented the mission of state-owned enterprises, actively promoted the national low-carbon and digital development concept, and focused on improving the breadth, depth and strength of technology. Based on the high recognition of ABB’s digital distribution solution, Qilu Petrochemical adopted ABB UniGear ZS1 digital medium-voltage switchgear, ABB AbilityTM MyRemoteCare equipment health management and ABB ZEE600 intelligent distribution management solutions to build a remote management and predictive maintenance system, further improve the reliability of power consumption and operation and maintenance efficiency at the enterprise site, and improve the level of lean production and operation, It has set a good example for the green and intelligent transformation of the domestic energy industry.

Liu Jiaqing, head of the electrical section of Qilu Petrochemical Operation and Maintenance Center, said, “Qilu Petrochemical has earlier tried to use ABB intelligent medium-voltage switchgear in Sinopec Group. This technology has helped us open new ideas for the subsequent green upgrading of the industry. In the future, we will continue to focus on the” double carbon “goal, deepen cooperation with ABB in other new substations, and strive to create green energy * * *, Set an example for the green transformation of the domestic petrochemical industry. ”

Deep integration of the Internet of Things technology, ABB UniGear ZS1 realizes the * * * perception of equipment health status through the mutual cooperation of built-in intelligent sensors, proactively predicts the failure risk of key equipment, and effectively improves the safety, ease of use and reliability of substation operation. The remote management and visual operation system enables the operation and maintenance personnel to grasp the substation equipment information more intuitively and * * *, meet the on-site operation and maintenance management requirements, and “protect” the equipment health in the whole life cycle. With the seamless integration capability in the electrical digital solution, ABB ZEE600 intelligent system can be connected to other substations, and can connect, analyze, optimize and control the energy network in a full range to meet the overall requirements of power quality management and energy efficiency management.

At present, ABB UniGear ZS1 digital switch cabinet has been successfully applied in Qilu Petrochemical Liuteng substation. In the future, the two sides will continue to focus on the goal of “carbon neutrality”, deepen cooperation in other new substations, and provide more transformation experience for the domestic petrochemical industry.

3BHB003154R0101

3BHB003230R0101

3BHB003387R0101

3BHB012961R0001

3BHB012961R0002

3BHB020538R0001

3BHE014105R0001

3BHE022333R0101

3BHL000385P0101

3BHL000387P0101

3BHL000389P0104

3BHL000390P0104

3BHL000391P0101

3BHL000392R0101

3BHL00391P0101

3BSE084741R1

3HB012961R0001

3HNA023093-001

5SDF0860H0003

5SHK0845F0001

5SHX0660F0001

5SHX0660F0002

5SHX06F6004

5SHX0845F0001

5SHX08F4502

5SHX1060H0001

5SHX1060H0003

5SHX1060H001

5SHX10H6004

5SHX1445H0001

5SHX1445H0002

5SHX14H4502

5SHX1960L0004

5SHX2645L0002

5SHX2645L0004

5SHX2645L0006

5SHX26L4510

5SHY3545L0003

5SHY3545L0005

———————————————————-

[Disclaimer]

Our company sells new products and discontinued products, and purchases such special products through independent channels. Guizhou Yuanmiao Automation Equipment Co., Ltd. is not an authorized distributor, distributor or representative of the featured products of this website. All product names/product images, trademarks, brands and microlabels used on this website are the property of their respective owners. Product descriptions, descriptions or sales with these name images, trademarks, brands and logos are for identification purposes only and do not represent any association or authorization with any right holders.